SCHINDMACHINES PNCH8000 CNC PROFILE PUNCHING and CUTTING MACHINE

With the experience we have gained in hydraulic profile punching machine manufacturing, we offer to our customers better solutions than drilling and laser cutting methods to create holes and slots on the materials of different types and thicknesses...

| Brand: | SCHIND |

| Category: | Machine , Metal Forming Machines |

| Origin: | Turkiye |

| Minimum Order: | 1 |

PRODUCT DESCRIPTION

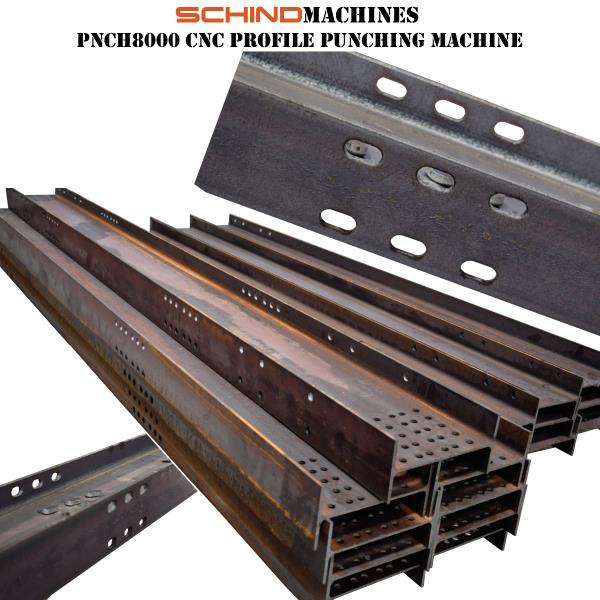

SCHIND Metal Profile Punching Machine is a best, fast and low cost workmate for you if you need to open holes or slots on your workpieces. Our Hydraulic Puncher can punch any straight shape profiles, pipes, C-profiles, U-profiles, flat bars, aluminum, W beams, IPE, HEA, HEM, HEB, NPU, NPI, UPN profiles for home / factory constructions, solar panel assembling, shelf box profile etc... It is faster than CNC laser cutting machine and CNC drilling machines. Plus, it has low cost investment, and less production cost. Excellent accuracy by the help of servo motors, CNC controller software, well known components and years of experience...

You can use our Full Automatic Hydraulic Tube Hole Punching Machine to produce Storage Rack Shelves and for many metal production purpose such as Guardrail Hole Punching, Square Profile Hole Punching, Round Pipe Hole Punching, Angle Bar Hole Punching, Fence Post Notching, Electric pole punching etc... Our CNC Automatic Punching Machine is Made in TURKIYE

PNCH8000 CNC Automatic Punching Machine is useful to produce supermarket shelf racks, solar panel field mounting poles, C-profiles, straight shape profiles, pipes, U-profiles, circle and square profiles. Different shape and dimensions holes and slots can be punched till 12mm thickness from any type metal.

Whole assembling holes and slots must be punched before installation of solar panels on the field mounting systems. Solar companies prefer to use W beam style profiles on the ground due to durability. And because of that reason they need profile punching machine or they need ready profile product. So, many companies get in touch with us about w beam profile punching machine or serial production under our roof according to their technical drawings. As Schind Machines, we also provide contract manufacturing services to our customers. With the experience we have gained in the manufacturing of punched profiles, flat sheets, pipes, H beam and NPU punching machines, we carry out the mass production works of our customers in-house.

Operator can punch holes between Ø11mm and Ø21mm or slots between 20x12 and 45x16mm on metal poles for solar PV farm structures such as IP, HA, W Beam with dimensions of 150x100, 150x150, 200x100mm with thicknesses between 4mm and 12mm. In an average working shift of 8 hours, production quantity will be between 400 - 500 pieces, depending on the solar panel mounting profiles length. We can punch all three surfaces of the solar farm ground mounting systems in different axes and at different sizes. We can punch 8 different holes on the same surface. For more information, please send your technical drawings to info@schindmachines.com

Hydraulic Tanks 180 Liters (48 Gallons) and UP

Siemens Servo Motor

Liming Zero-Backlash Planet Reducer

Framo Morat & Hiwin Linear Guide

Helical Rack Gear System

Automation System Siemens S7 1200

Hydraulic Cutting Scissors

Safety Barrier with Laser, Fence, Mat is possible

You can use our Full Automatic Hydraulic Tube Hole Punching Machine to produce Storage Rack Shelves and for many metal production purpose such as Guardrail Hole Punching, Square Profile Hole Punching, Round Pipe Hole Punching, Angle Bar Hole Punching, Fence Post Notching, Electric pole punching etc... Our CNC Automatic Punching Machine is Made in TURKIYE

PNCH8000 CNC Automatic Punching Machine is useful to produce supermarket shelf racks, solar panel field mounting poles, C-profiles, straight shape profiles, pipes, U-profiles, circle and square profiles. Different shape and dimensions holes and slots can be punched till 12mm thickness from any type metal.

Whole assembling holes and slots must be punched before installation of solar panels on the field mounting systems. Solar companies prefer to use W beam style profiles on the ground due to durability. And because of that reason they need profile punching machine or they need ready profile product. So, many companies get in touch with us about w beam profile punching machine or serial production under our roof according to their technical drawings. As Schind Machines, we also provide contract manufacturing services to our customers. With the experience we have gained in the manufacturing of punched profiles, flat sheets, pipes, H beam and NPU punching machines, we carry out the mass production works of our customers in-house.

Operator can punch holes between Ø11mm and Ø21mm or slots between 20x12 and 45x16mm on metal poles for solar PV farm structures such as IP, HA, W Beam with dimensions of 150x100, 150x150, 200x100mm with thicknesses between 4mm and 12mm. In an average working shift of 8 hours, production quantity will be between 400 - 500 pieces, depending on the solar panel mounting profiles length. We can punch all three surfaces of the solar farm ground mounting systems in different axes and at different sizes. We can punch 8 different holes on the same surface. For more information, please send your technical drawings to info@schindmachines.com

SPECIFICATIONS

Machine Power from 10 tons to 500 Tons.Hydraulic Tanks 180 Liters (48 Gallons) and UP

Siemens Servo Motor

Liming Zero-Backlash Planet Reducer

Framo Morat & Hiwin Linear Guide

Helical Rack Gear System

Automation System Siemens S7 1200

Hydraulic Cutting Scissors

Safety Barrier with Laser, Fence, Mat is possible

SIMILAR PRODUCTS

-

Metal Forming Machines

Schind CKF-H 2535 × 3,5mm Hydraulic Heavy Duty Folding Machine

-

Metal Forming Machines

-

Metal Forming Machines

-

Metal Forming Machines

-

Metal Forming Machines

-

Metal Forming Machines

SCHINDMACHINES SSG300-1R, SSG300-2R, SSG300-3R FLAT METAL SURFACE SANDING MACHINE

TÜRKÇE

TÜRKÇE

ENGLISH

ENGLISH

عربى

عربى

русский

русский

Español

Español