SCHINDMACHINES CNCPB Ø42x3mm 5 AXIS CNC PIPE BENDING MACHINE with ROLLING, PUNCHING and CUTTING FEATURE

The most distinctive feature of our Schind CNCPB Ø42 model multi-axis pipe bending machine is its ability to make rolling. 5 axis CNC not only provides the advantage of mass production, but also eliminates operator errors and allows you excelent result.

| Product Code: | CNCPB 42 |

| Brand: | SCHIND |

| Category: | Machine , Pipe and Tube Bending Machines |

| Origin: | Turkiye |

| Minimum Order: | 1 |

| Max. Pipe Wall Thickness: | 3mm |

| Max. Bending Angle: | 210° |

| Engine Power: | 3kW |

PRODUCT DESCRIPTION

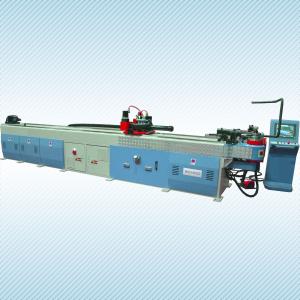

5 Axis CNC pipe bending machine is the professional CNC bending machine needed to produce consecutive bends of standard pipes up to Ø42 and 3mm thick and less in mass production logic. Our Schind CNCPB Ø42 pipe bending model, which can be connected to 3 different molds and to which we have added punching and cutting features in the molds, appeals to all our customers who love automation. Another feature of our CNC pipe bending machine is the rolling ability to produce ellipse and round shapes. When bending standard pipes of 6 meters length, the bending head is rotated at the desired angle to bend the pipe or rectangular tube is bent by feeding it with the holding arm. Since the machine makes all its movements using a servo motor and a ball screw, measurement accuracy is at maximum level.

| SCHIND CNCPB Ø42 x 3 mm TECHNICAL SPECIFICATIONS |

| ➢ Maximum Bending Capacity: Ø42 x 3 mm |

| ➢ Material Processing Length: 6000 mm |

| ➢ Maximum Mold Diameter: 250 mm |

| ➢ Minimum Mold Diameter: 50 mm |

| ➢ Direct Drawing Transfer to the Machine with Step File |

| ➢ Servo Bending, Feed Rotation and Dimensioning |

| ➢ 3D Simulation Preview |

| ➢ Easy to Use Thanks to the Interface |

| ➢ Ability to Bend 3 Different Radius in the Same Pipe |

| ➢ Rolling Twisting Feature |

| ➢ Maximum Twisting Angle 210° |

| ➢ Ability to See Errors on the Screen |

| ➢ Safety Warning System |

| ➢ Unlimited Prescription Recording in Memory |

| ➢ Windows 10, 21” Touch Screen |

| ➢ 3 Different Language Options: Turkish, English and Customer Language |

| ➢ Twisting Motor Power 3 kW |

| ➢ Voltage: 400VAC 3PHASE 50hz |

| ➢ Control Panel: 24 VDC |

| ➢ Instant Voltage Current Maximum 18 KW |

| ➢ HIWIN Rail, Carriage and Backlash Free Ball Screw |

| ➢ GAMBINI Helical Rack and Pinion |

| ➢ DELTA Servo Motors and LIMING Reducers Used |

| ➢ CNC Machine Control |

| ➢ Electrical Panel Materials Siemens Lenze |

| ➢ Motor Drives DELTA |

| ➢ Motor Protection Unit DELTA |

| ➢ Feed Speed 25 m/min |

| ➢ 1 year Warranty |

| ➢ Produced with CE Norms. |

| ➢ Machine Dimensions (W, W, H) 1600 x 1650 x 9500 mm |

| ➢ Weight 4650 Kg |

| ➢ X Axis 1500 Watt Servo Motor Speed Controlled 2000 Rpm |

| ➢ Y Axis 2200 Watt Servo Motor Speed Controlled 1500 Rpm |

| ➢ A Axis 750 Watt Servo Motor Speed Controlled 3000 Rpm |

| ➢ C Axis 3000 Watt Servo Motor Speed Controlled 1500 Rpm |

| ➢ Z Axis 2200 Watt Servo Motor Speed Controlled 1500 Rpm |

| ➢ X Axis Linear Slide – HIWIN, 45mm (A TYPE) |

| ➢ Y Axis Linear Slide – HIWIN, 45mm (B TYPE) |

| ➢ Z Axis Linear Slide – HIWIN, 25mm (B TYPE) |

SIMILAR PRODUCTS

-

Pipe and Tube Bending Machines

Mandrel Pipe and Tube Bending Machine NCPB 01 - Ø32 - Hydraulic - NC

-

Pipe and Tube Bending Machines

NCPB Ø65 NC Controlled Pipe and Tube Bending Machine with Mandrel

-

Pipe and Tube Bending Machines

CNC Pipe and Tube Bending Machine CNCPB 04 - 65 Ø - Full Automatic

-

Pipe and Tube Bending Machines

-

Pipe and Tube Bending Machines

Tube Bending Machine SCHIND NCPB Ø76 - Hydraulic Mandrel - NC

-

Pipe and Tube Bending Machines

Mandrel Pipe and Tube Bending Machine MPB - Ø32 - Semi Automatic - Mechanical

TÜRKÇE

TÜRKÇE

ENGLISH

ENGLISH

عربى

عربى

русский

русский

Español

Español