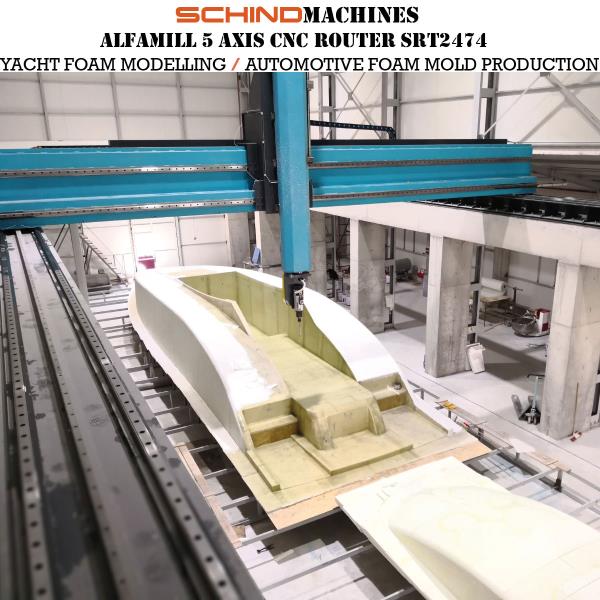

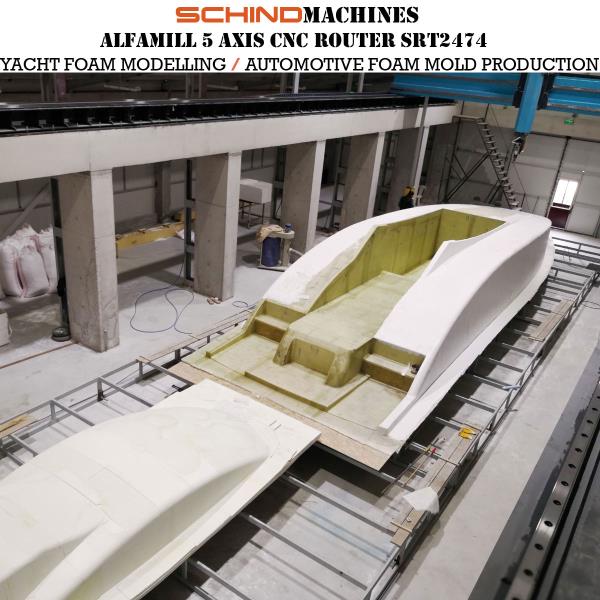

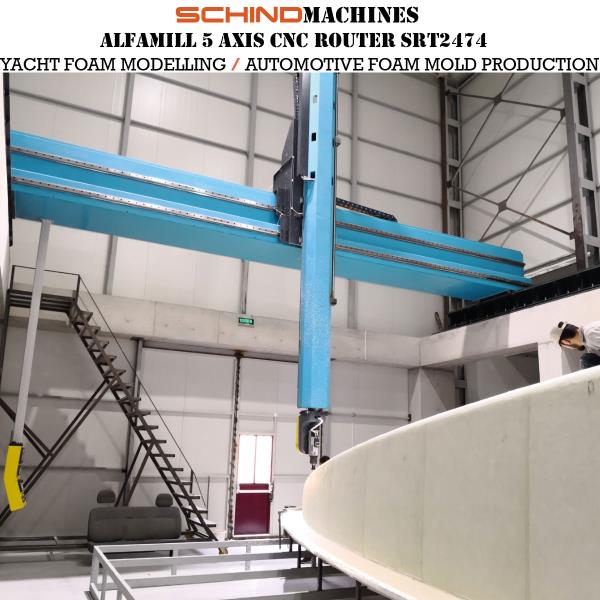

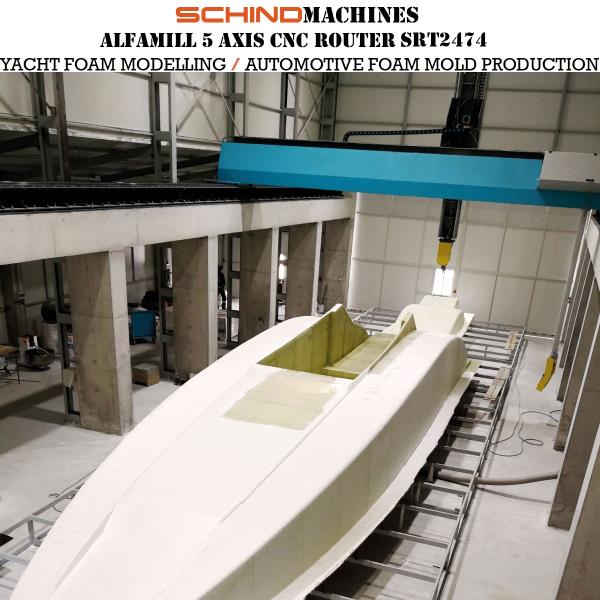

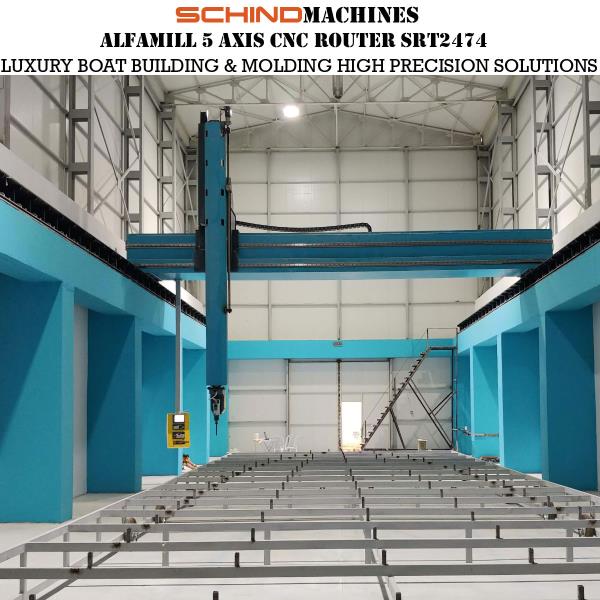

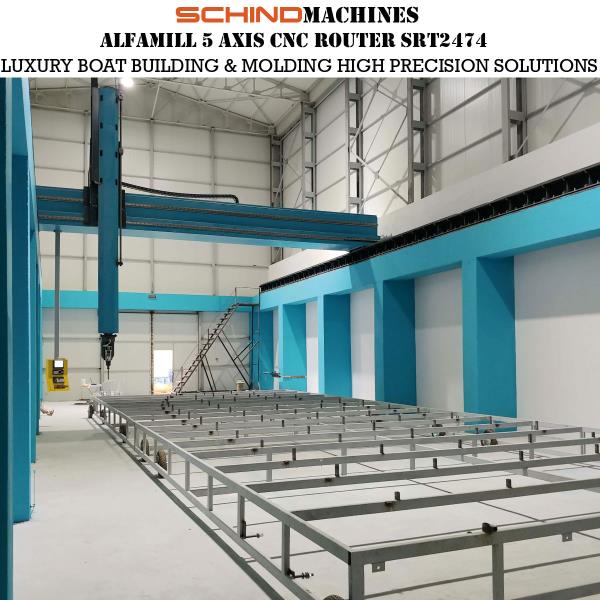

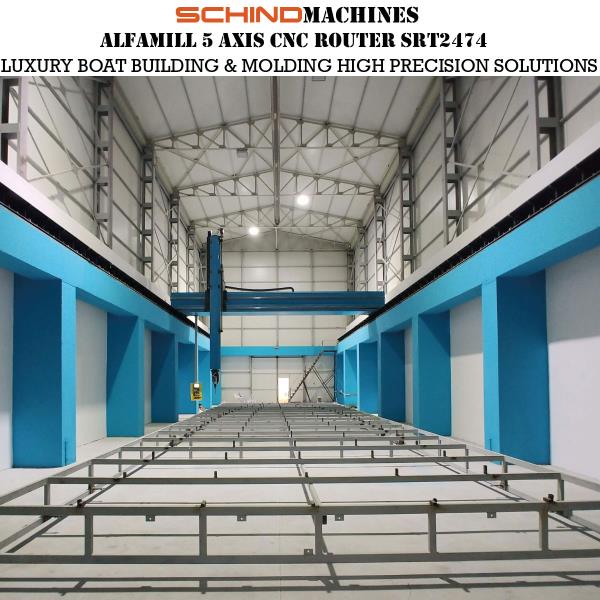

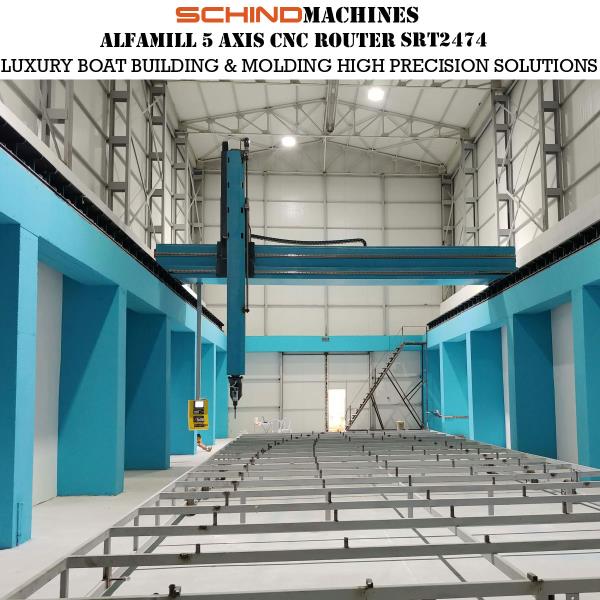

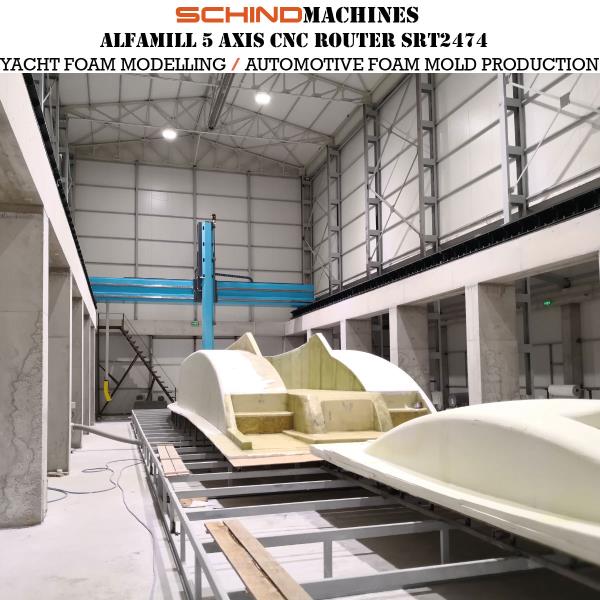

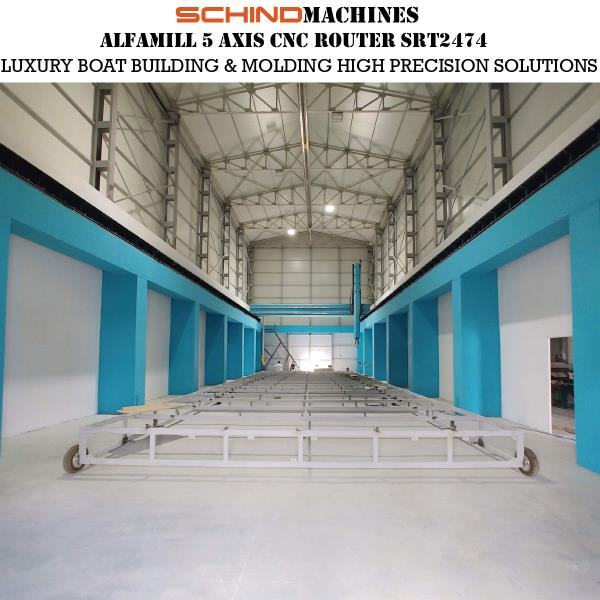

SCHIND MACHINES ALFAMILL 5 AXES CNC ROUTER SRT2474

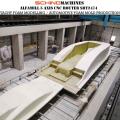

Manufacturing foam molds requires a precise 5-axis CNC milling router. Our Schind SRT2474 model is one of the largest CNC routers and is a machine used in the production of molds of luxury yachts, automotive modeling or ship spare parts production.

| Brand: | SCHIND |

| Category: | Machine , Marble, Natural Stone and Granite Machines |

| Origin: | Turkiye |

| Minimum Order: | 1 Pc |

PRODUCT DESCRIPTION

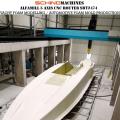

We developed our longest 5 axis cnc router machine SRT2474 for cnc foam mold forming of yacht and automotive production. All boat producers needs to prepare their prototype first to make the shape of boards materials for modelling and mold. Yacht foam modelling or automotive foam mold production from polystyrene foam block are not easy and need extra ordinary engineering. 5 axis cnc router engraving and milling foam is easy with our Schind SRT2474 cnc model forming router. Our 5 axis foam cnc router machine in this link is produced according to customer demand to make luxury yacht models from styrofoam blocks.

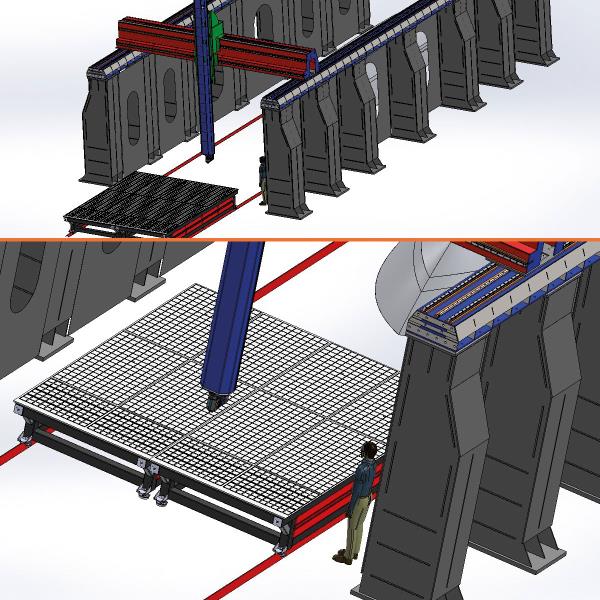

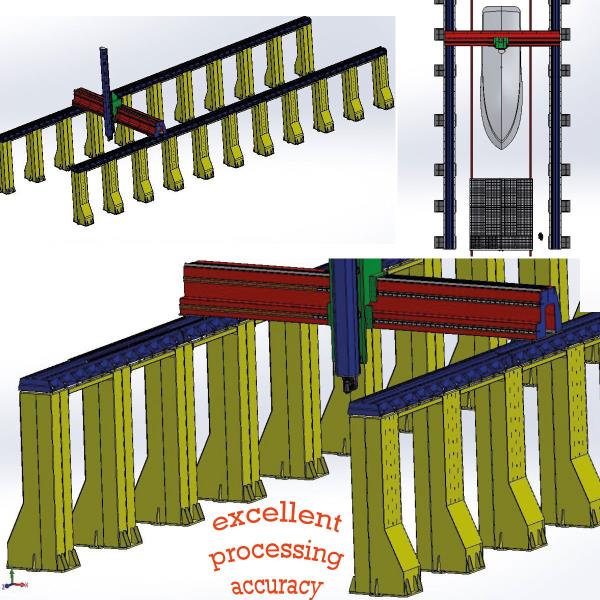

We have enough experiences for special shipyard and aerospace mold patterns 5 axes solutions. Schind Machines SRT2474 styrofoam mold making cnc router machine is equipped for three-dimensional engraving, drilling, slotting, milling, cutting. Big sized milling capacity five-axis machining widely used in yacht mold and model manufacturing from high-density polyurethane foam carving blocks. Our cnc foam routing machine has high accuracy five-axis head to be able to cnc engraving for DIY model sculpture mold making. In our cnc foam mold milling machine we prefer to use Mastercam / Alphacam Software. Cnc router machining specification and combinations may vary according to customer works which make mold making from foam, fiberglass, wood, epoxy, board etc.

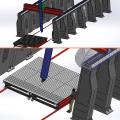

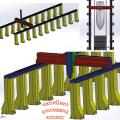

Our priority in our machines is to minimize the margin of error in such a long-distance cnc processing system. Therefore, mechanically, we do well in the combination of high-precision pinions with low-backlash planetary gearboxes and rack and pinion gears. Our machine positions its axes accurately with micrometer precision during operation, and the first-class thick rail, rack and pinion we use provides high strength to our machine and extends the processing life of the machine.

We have enough experiences for special shipyard and aerospace mold patterns 5 axes solutions. Schind Machines SRT2474 styrofoam mold making cnc router machine is equipped for three-dimensional engraving, drilling, slotting, milling, cutting. Big sized milling capacity five-axis machining widely used in yacht mold and model manufacturing from high-density polyurethane foam carving blocks. Our cnc foam routing machine has high accuracy five-axis head to be able to cnc engraving for DIY model sculpture mold making. In our cnc foam mold milling machine we prefer to use Mastercam / Alphacam Software. Cnc router machining specification and combinations may vary according to customer works which make mold making from foam, fiberglass, wood, epoxy, board etc.

Our priority in our machines is to minimize the margin of error in such a long-distance cnc processing system. Therefore, mechanically, we do well in the combination of high-precision pinions with low-backlash planetary gearboxes and rack and pinion gears. Our machine positions its axes accurately with micrometer precision during operation, and the first-class thick rail, rack and pinion we use provides high strength to our machine and extends the processing life of the machine.

SIMILAR PRODUCTS

-

Marble, Natural Stone and Granite Machines

-

Marble, Natural Stone and Granite Machines

SCHIND 16403 PLC - Marble, Stone and Granite Cutting Machine

-

Marble, Natural Stone and Granite Machines

SCHINDMACHINES SMW10 MULTI WIRE GRANITE & MARBLE BLOCK CUTTING MACHINE

-

Marble, Natural Stone and Granite Machines

SCHINDMACHINES MIDDLE BRO 3520CAM 5 AXIS CNC SLAB CUTTING & MILLING MACHINE

-

Marble, Natural Stone and Granite Machines

-

Marble, Natural Stone and Granite Machines

TÜRKÇE

TÜRKÇE

ENGLISH

ENGLISH

عربى

عربى

русский

русский

Español

Español