| Product Code: | SPLB-1530 |

| Brand: | SCHIND |

| Category: | Machine , Plasma Cutting Machines |

| Origin: | Turkey |

| Minimum Order: | 1 |

| Power Source: | HYPERTHERM |

| Working Table Size (mm): | 1500x3000 |

| Working Table Extraction System: | Automatic dust and fume extraction system |

PRODUCT DESCRIPTION

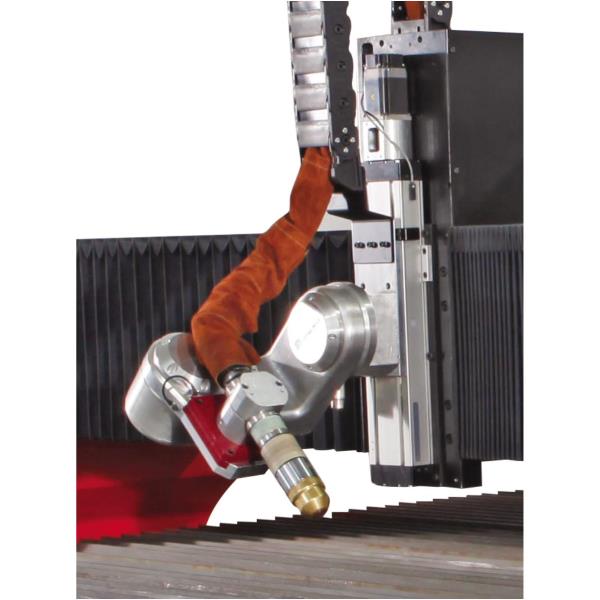

SCHIND CNC Plasma Cutting Machine

Although it is a technology dating back to the 1950s, CNC plasma cutting machines are actively preferred machines, especially in the construction sector.

Schind CNC plasma cutting machines are an efficient solution for thicknesses where fiber laser cutting technology is insufficient. Plasma cutting machines are preferred due to their ability to make multiple cuts on the same table, minimum consumption even in thick materials, and fast cutting features.

CNC plasma cutting machines, with the ability to process thicknesses up to a maximum of 180 mm, are more efficient than other technologies, even at the highest performance level. Cutting cost, time, raw material savings and cnc cutting possibilities make plasma cutting machines efficient.

Schind CNC plasma cutting machines, which also have pipe cutting and angled cutting options, are an option that increases productivity and shortens the processing time in works that require metalworking. You can examine our Schind SPLB for angled cutting and Schind SPL TUBE for pipe cutting. In addition, we offer you economical solutions with the pipe cutting option in our Schind SPLB angled plasma cutting machine.

The prices of CNC plasma cutting machines are much more economical than the prices of fiber laser cutting machines. It is a logical choice in high thicknesses, in the construction industry, in works that require metalwork, and in mass production areas.

Some options are available for worktable size and plasma source.

STANDART EQUIPMENT

- 5 Axis Automatic Cutting Head

- Hypertherm Edge Connect CNC

- Hypertherm Plasma Power Source

- 19,5'' Touch Screen

- Hypertherm Pronest Nesting software

- True Bevel Technology

- True Hole Technology

- Pause / resume last part

- Torch Collision Protection System

- Automatic Torch Height Controle

- Axis positioning accuracy ± 0,02 mm

- Axis positioning seed max. 20 m/min.

- Remote assistance

- Laser pointer for plate alignment

- Automatic dust and fume extraction system

OPTIONAL EQUIPMENT

- Plasma Power Sources

-- HPRXD Series

> HPR400XD

> HPR800XD

-- XPR Series

> XPR170 - choice of CORE / VWI / OPTIMIX Automatic Gas consoles

> XPR300 - choice of CORE / VWI / OPTIMIX Automatic Gas consoles

- Oxy Cutting System with capacitve sensor system

- Oxy Cutting System wtih Auto Gas Console

- Tube Cutting

- SCHIND Jet Filter

- Lateral Drawers for slag collection system

SIMILAR PRODUCTS

-

Plasma Cutting Machines

-

Plasma Cutting Machines

-

Plasma Cutting Machines

-

Plasma Cutting Machines

-

Plasma Cutting Machines

-

Plasma Cutting Machines

TÜRKÇE

TÜRKÇE

ENGLISH

ENGLISH

عربى

عربى

русский

русский

Español

Español